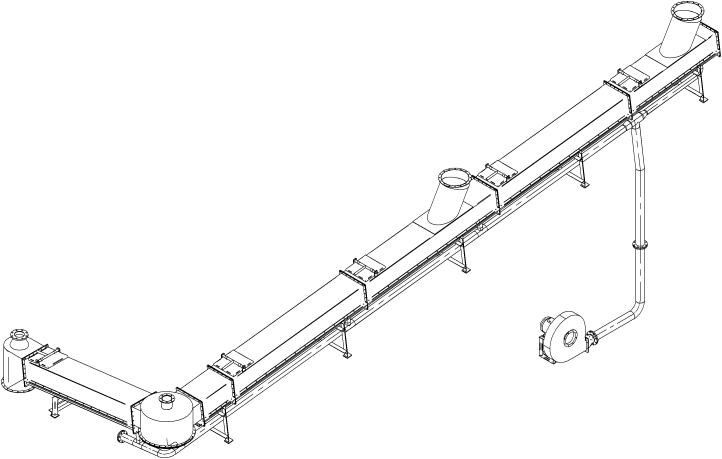

The air conveying chute is a pneumatic conveying equipment used to convey dry powdery materials with a moisture content of ≤1% and a temperature of ≤150℃. Generally include feed inlet, standard section, non-standard section, shut-off valve, curved groove, three-way groove, rain cover, discharge leak, trough frame and chute air supply device, etc. (as shown in the figure). The trough body is made of Q235-A material, the chute trough body wall thickness δ3mm smaller than XZ500 (including XZ500) is made of steel plate, and the chute trough body wall thickness δ4mm larger than XZ630 (including XZ630) is made of steel plate, which is smaller than XZ500 The chute connecting flange (including XZ500) is made of steel plate with a wall thickness of δ6 mm, and the chute connecting flange of XZ630 (including XZ630) is made of steel plate with a wall thickness of δ8 mm. The breathable layer is made of PET5-6 synthetic fiber for ventilation. The canvas is δ6mm thick, and the perforated plate is δ2mm steel plate.

The air chute manufacturing and installation methods can be selected according to the needs of the overall installation and the graded assembly two methods; the overall installation is to make the shell into parts, and the lower tank body is installed and fixed on the spot, and the breathable canvas is continuously laid on the whole without breaking. On the lower tank, then install and tighten the upper tank. Use rubber sheet or asbestos rope as sealing material between flanges. When grading assembling, first make the chute into an integral section containing breathable canvas according to the standard section or non-standard section, and use the special "day"-shaped gasket as the seal during on-site installation. The manufacturing and installation method can be determined by the user when ordering.

Because the air conveying chute has no rotating parts, it is easy to maintain, has good sealing, no noise, reliable operation, low power consumption, convenient to change the conveying direction, and can feed and discharge more points.

The air conveying chute must strictly control the moisture content of the conveyed material, such as rain-proof type and rain-proof cover when it is laid out in the open air.

Icon:

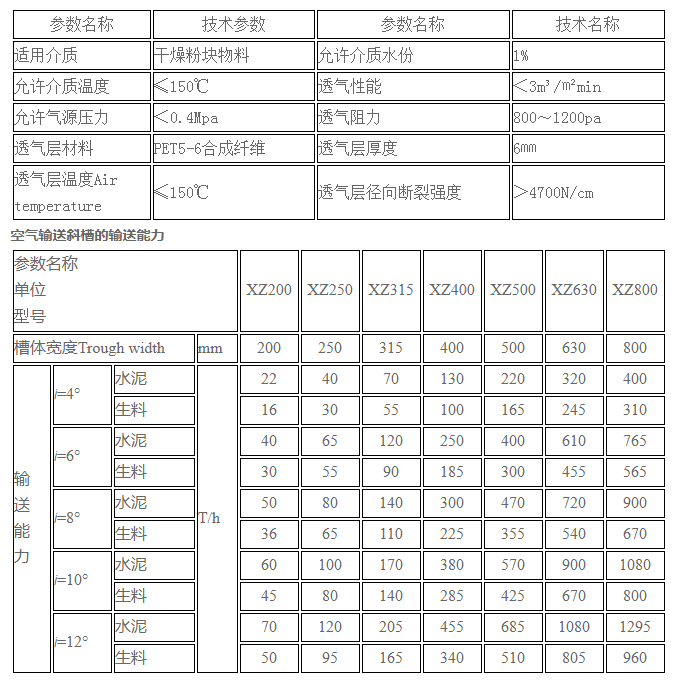

Technical parameters of air conveying chute